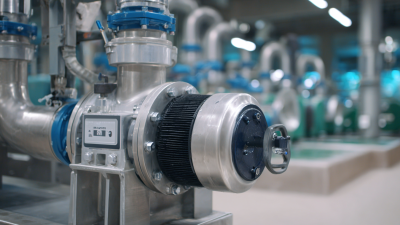

Understanding the Advantages of Electric Actuated Ball Valves in Modern Industrial Applications

In recent years, the adoption of electric actuated ball valves has significantly transformed modern industrial applications, driven by the need for efficiency and precision in fluid control systems. According to a report by the Global Industry Analysts, the market for electric actuated valves is projected to grow at a CAGR of 6.5% through 2027, reflecting their increasing importance in various sectors, including oil and gas, water management, and manufacturing.

The benefits of electric actuated ball valves include enhanced reliability, reduced maintenance costs, and improved automation capabilities, making them ideal for sophisticated industrial environments. Moreover, with the advent of IoT technologies, these valves can now be integrated into smart systems for real-time monitoring and control.

This evolution underscores the critical role that electric actuated ball valves play in optimizing operational efficiency and safety in today’s industrial landscape.

Advantages of Electric Actuated Ball Valves Over Traditional Valves

Electric actuated ball valves are increasingly popular in modern industrial applications, offering several distinct advantages over traditional valves. One notable benefit is precision control. With electric actuators, these valves provide accurate positioning and can be easily integrated into automated control systems. This level of control minimizes the risk of human error and enhances the overall efficiency of fluid management processes.

Another significant advantage is improved reliability. Electric actuated ball valves are designed to operate without the manual intervention required by traditional valves, reducing wear and tear caused by frequent opening and closing. This leads to longer operational life and fewer maintenance requirements, making them a cost-effective solution in the long run. Additionally, these valves can be equipped with advanced monitoring systems that allow for real-time data collection and diagnostics, further ensuring optimal performance in various industrial environments.

Key Considerations for Selecting Electric Actuated Ball Valves

When selecting electric actuated ball valves for industrial applications, several key considerations come into play. Firstly, the compatibility of the valve material with the process fluid is vital. According to a recent market report by Grand View Research, the global ball valve market is expected to reach USD 7.2 billion by 2027, indicating a growing need for reliable components that can handle diverse media types safely and efficiently. Selecting valves made from appropriate materials will ensure longevity and reduce maintenance costs.

Another critical factor is the power requirements of the electric actuator. The choice between AC and DC actuators can significantly affect installation and operational efficiency. For instance, a study from Markets and Markets indicated that DC actuators provide enhanced control and energy efficiency in low-power applications, making them suitable for smaller systems where precision is paramount. Understanding the application demands will aid in selecting a valve that meets both performance criteria and energy consumption goals.

Tip: Always consider the valve’s response time and position feedback options. These features can improve system performance and facilitate better control processes, especially in automated environments. Additionally, check for compliance with relevant industry standards to ensure both safety and efficiency in operations.

Maintenance Best Practices for Electric Actuated Ball Valves

When it comes to electric actuated ball valves, proper maintenance is critical to ensuring their longevity and optimal performance in industrial applications. Regular inspection of the valve and actuator components can prevent unexpected failures. It is advised to check for signs of wear or damage, including the integrity of seals and the smooth operation of the actuator. Lubrication of moving parts, adhering to the manufacturer’s specifications, plays a vital role in maintaining functionality and avoiding operational hiccups.

As industries prepare for seasonal changes, such as irrigation shutdowns, it's essential to implement best practices tailored to the specific environment and application of these valves. When shutting down systems, a thorough evaluation of the valves can prevent issues during the restart phase. Moreover, ensuring that electric connections are secure and that the control systems are calibrated correctly can significantly minimize downtime.

Regular training and education on maintenance protocols for personnel also help in fostering a proactive approach to valve care, ultimately enhancing operational efficiency and reliability.

Applications of Electric Actuated Ball Valves in Various Industries

Electric actuated ball valves have become an integral component in various industrial applications due to their efficiency and precision. In the oil and gas industry, these valves facilitate the control of flow rates and pressure levels, significantly enhancing safety and operational reliability. Their ability to automate processes reduces the need for manual intervention, allowing for real-time monitoring and adjustment, which is critical in environments where conditions can change rapidly.

In the pharmaceutical and food processing sectors, cleanliness and hygiene are paramount. Electric actuated ball valves offer a streamlined way to manage the flow of substances through piping systems without the risk of contamination, thanks to their tight sealing capabilities. Additionally, they can be integrated into sophisticated control systems, ensuring that processes adhere to stringent regulatory standards while maintaining product integrity and consistency. The versatility of these valves across diverse applications reinforces their importance in modern industrial operations, making them a strategic choice for optimizing process efficiency.

Future Trends in Electric Actuation Technology for Industrial Valves

Electric actuated ball valves are gaining traction in modern industrial applications due to their efficiency and precision. As industries continue to evolve, the future trends in electric actuation technology are set to revolutionize the way these valves operate. One significant trend is the integration of smart automation. With the Internet of Things (IoT) becoming ubiquitous, electric actuators are now being designed with connectivity features that allow for remote monitoring and control. This capability not only enhances operational efficiency but also enables predictive maintenance, reducing downtime and maintenance costs.

Another emerging trend is the improvement in energy efficiency and sustainability. New advancements are focused on using low-energy designs that require minimal power for operation, which aligns with global efforts towards greener practices. Manufacturers are increasingly optimizing materials and designs to reduce the carbon footprint of these valves.

Tips: When selecting electric actuated ball valves for your applications, consider opting for models with built-in smart technology features. This will not only streamline operations but also provide you with valuable data insights. Additionally, explore options that prioritize energy efficiency to contribute to your sustainability goals while reducing operational costs.

Advantages of Electric Actuated Ball Valves in Modern Industrial Applications

Related Posts

-

Discover Top Quality Electric Valves from Leading Manufacturers in China

-

Exploring the Impact of Motorized Valve Technology on Energy Efficiency in Industrial Applications

-

Global Excellence in Control Valve Manufacturing China Leads the Way

-

7 Essential Benefits of Using High Pressure Ball Valves in Industrial Applications

-

Understanding the Purpose and Functionality of Flow Control Valves

-

Understanding the Mechanism Behind Ball Check Valves