How to Choose the Right Water Valve for Your Industrial Needs

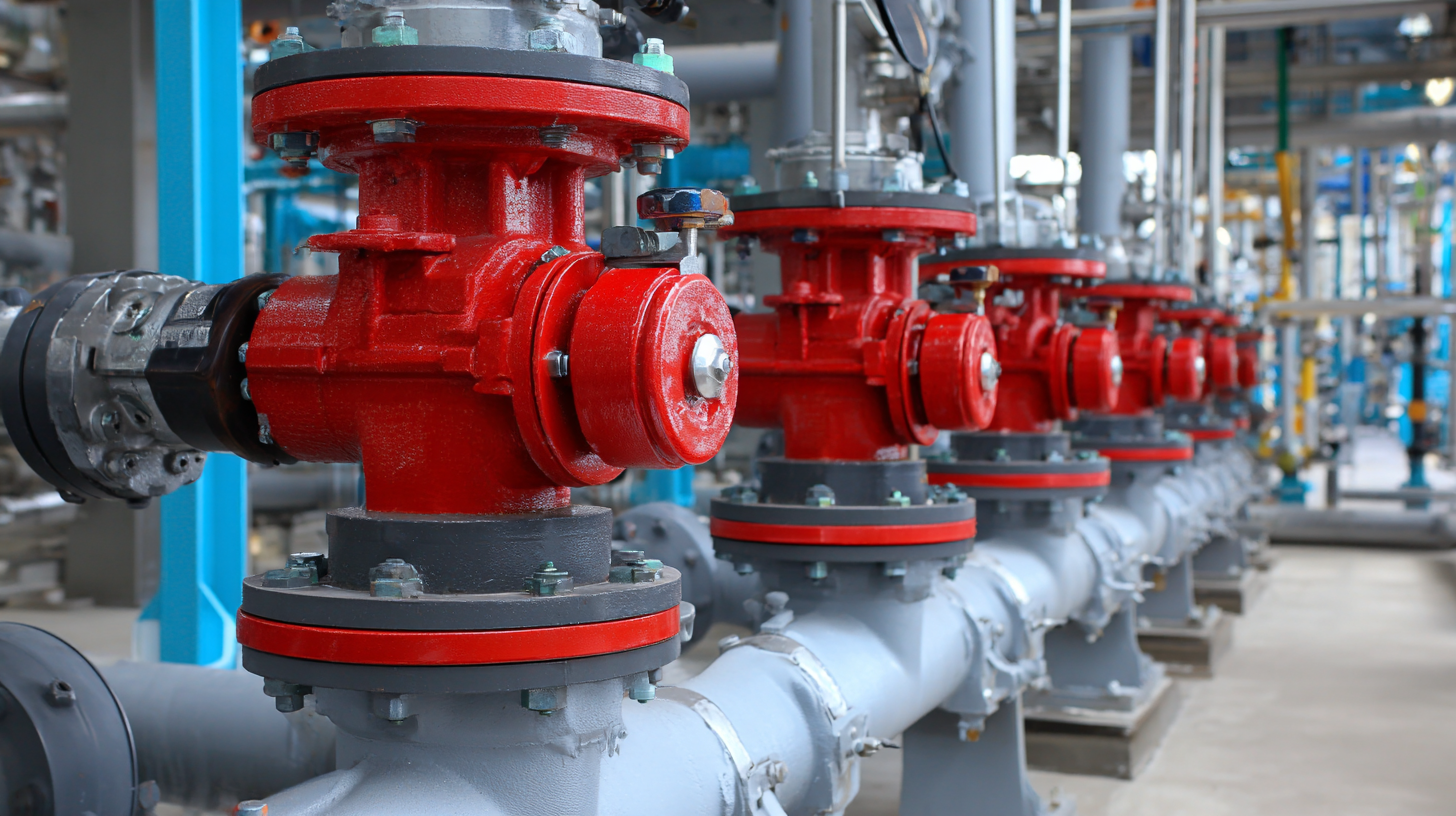

When selecting a water valve for industrial applications, it's crucial to understand the various types available and their specific functionalities. According to a recent report by MarketsandMarkets, the global industrial valve market is projected to reach $80.5 billion by 2025, driven by increasing demand for water and wastewater treatment, as well as the rising importance of efficient fluid management. Water valves play a pivotal role in regulating the flow of fluids, ensuring operational efficiency, and maintaining safety standards across various sectors. With numerous types of water valves, including gate, globe, ball, and butterfly valves, each serves distinct purposes that cater to different industrial settings. This blog will guide you through the essential factors to consider when choosing the right water valve for your industrial needs, ensuring that your selection enhances both performance and reliability in your operations.

Choosing the Right Water Valve: Understanding Key Specifications and Standards for Industrial Use

When selecting the right water valve for industrial applications, understanding key specifications and standards is essential for ensuring optimal performance and reliability. The first critical specification to consider is the valve material, which should be compatible with the fluids being processed. Common materials include brass, stainless steel, and PVC, each offering distinct advantages in terms of durability, corrosion resistance, and pressure ratings. It’s crucial to match the valve material to not only the media but also the environmental conditions to prevent premature failure.

Additionally, understanding industry standards, such as ANSI, API, and ISO, will enable you to choose a valve that meets safety and operational requirements. Each standard provides guidelines for performance criteria, testing methods, and quality assurance measures. It’s also advisable to pay attention to flow rate and pressure ratings specified by these standards, as they can significantly impact the efficiency and safety of your system. By carefully evaluating these specifications and standards, you can select a water valve that not only meets the immediate needs of your industrial application but also promotes long-term reliability and maintenance efficiency.

How to Choose the Right Water Valve for Your Industrial Needs

| Valve Type | Material | Pressure Rating | Temperature Range | Standard Compliance |

|---|---|---|---|---|

| Gate Valve | Cast Iron | 150 PSI | -20 to 200 °F | API 6D |

| Globe Valve | Stainless Steel | 300 PSI | -40 to 650 °F | ASME B16.34 |

| Ball Valve | PVC | 100 PSI | -20 to 140 °F | ASTM D1784 |

| Check Valve | Bronze | 200 PSI | -20 to 300 °F | ANSI B16.10 |

| Butterfly Valve | Cast Iron | 150 PSI | -20 to 180 °F | API 609 |

Comparing Materials: The Impact of Brass, Stainless Steel, and Plastic on Valve Performance

When selecting a water valve for industrial applications, the material of the valve significantly impacts its performance and longevity. Brass valves are known for their strength and corrosion resistance, making them suitable for a variety of water applications. However, they may not be ideal for highly acidic or chlorinated waters, as the material can degrade over time. On the other hand, stainless steel valves offer excellent durability and resistance to a wide range of chemicals, making them a reliable choice for demanding environments.

Plastic valves, while lightweight and easy to install, can be limited in their temperature tolerance and may not withstand the same pressures as metal options. However, they present a cost-effective solution for less demanding applications, especially in water treatment and irrigation systems.

**Tip:** Always assess the specific conditions of your application, including temperature, pressure, and chemical exposure, before selecting the valve material.

**Tip:** Consult with a materials engineer or valve expert to ensure that the chosen valve material aligns with your system’s requirements, maximizing efficiency and longevity.

Comparison of Valve Material Properties

This chart compares the durability (in years) and corrosion resistance (on a scale from 0 to 10) of three common water valve materials: Brass, Stainless Steel, and Plastic. This information can help in making an informed choice based on specific industrial needs.

Flow Rate and Pressure Ratings: How to Optimize Efficiency in Industrial Water Systems

When selecting the right water valve for industrial applications, understanding flow rate and pressure ratings is essential for optimizing system efficiency. The flow rate determines how much water can pass through the valve at any given time, which is critical for maintaining productivity in operations. An inadequate flow rate can lead to bottlenecks, whereas a valve that exceeds necessary capacity may cause energy waste and excessive wear on system components. Therefore, it's vital to analyze the specific requirements of your water system and choose a valve that matches the expected flow demands.

Pressure ratings also play a crucial role in valve selection. Each valve is designed to operate within certain pressure limits, and exceeding these can lead to catastrophic failures and costly downtime. When evaluating pressure ratings, consider factors such as the maximum system pressure, the potential for pressure surges, and the effects of temperature variations. Properly matching the valve's pressure ratings to the operational conditions will not only enhance reliability but also contribute to an overall more efficient water system. By carefully assessing both flow rate and pressure requirements, industries can ensure they select a valve that optimally supports their operational goals.

The Importance of Valve Type Selection: Gate, Ball, and Butterfly Valves Explained

Choosing the right water valve for industrial applications is crucial, as different valve types serve varying purposes. Among the most common types are gate, ball, and butterfly valves. Gate valves are ideal for on/off control with minimal pressure drop, making them suitable for high-flow applications. However, they are not well-suited for throttling, as they can cause erosion and damage.

Choosing the right water valve for industrial applications is crucial, as different valve types serve varying purposes. Among the most common types are gate, ball, and butterfly valves. Gate valves are ideal for on/off control with minimal pressure drop, making them suitable for high-flow applications. However, they are not well-suited for throttling, as they can cause erosion and damage.

Ball valves, known for their durability and tight sealing capabilities, provide excellent flow control with low resistance. They are perfect for quick shut-off applications and can handle a wide range of pressures and temperatures. When selecting a ball valve, consider the material and design to ensure compatibility with the fluid being transported.

Butterfly valves are a lightweight, cost-effective option, perfect for large flow volumes and quick operations. They excel in regulating flow but may not be the best choice for high-pressure applications. When selecting a butterfly valve, pay attention to the actuator type to achieve the desired operation efficiency.

Tips: Always evaluate the specific requirements of your application, including the type of fluid, pressure, and temperature. Consult with a valve specialist to ensure you choose the most suitable option for your needs. Regular maintenance can extend the life of your valves and improve performance, regardless of the type you choose.

Maintenance and Longevity: Selecting Valves to Minimize Downtime and Replacement Costs

Selecting the right water valve for industrial applications goes beyond immediate performance; it requires a focus on maintenance and longevity to minimize costly downtime and replacement expenses. According to a report by the International Society of Automation (ISA), downtimes in industrial settings can cost companies between $2,000 to $20,000 per minute, depending on the industry. Therefore, investing in high-quality, durable valves can significantly reduce these occurrences. Valves made from corrosion-resistant materials such as stainless steel or specialized alloys not only ensure longer service life but also reduce the frequency of maintenance interventions.

In addition, regular maintenance schedules are essential for prolonging the lifespan of water valves. According to the American Water Works Association (AWWA), proactive maintenance can extend the life of a valve by up to 50%. Choosing valves that are easy to service and repair can further minimize the time spent in maintenance and lead to lower operational costs. Incorporating technology such as predictive maintenance systems can also help in identifying potential failures before they lead to major disruptions, allowing for timely interventions. By focusing on these aspects, industries can not only optimize their operations but also achieve significant cost savings over time.

Related Posts

-

How to Select the Best Pneumatic Valve for Your Industrial Applications

-

What Makes a Pneumatic Ball Valve the Best Choice for Industrial Applications

-

Top Strategies for Enhancing Efficiency with Pneumatic Valves in Industrial Applications

-

Elevating Global Standards through Best Control Valve Solutions Made in China

-

Top Strategies for Maximizing Efficiency with Electric Valves in Industrial Applications

-

7 Effective Strategies for Choosing the Right Electric Valve