Unlocking Efficiency: Technical Specifications of the Best 3 Way Ball Valve and How to Optimize Its Use

In the ever-evolving landscape of industrial automation and fluid control systems, the importance of efficient valve design cannot be overstated. Among the various types of valves, the 3 way ball valve stands out for its exceptional ability to facilitate smooth fluid flow while allowing for precise directional control. According to a recent industry report by MarketsandMarkets, the global ball valve market is projected to reach $4.9 billion by 2026, with a significant portion attributed to the increasing demand for 3 way ball valves in various applications, including oil and gas, water treatment, and chemical processing. This surge in demand underscores the necessity for professionals to understand the technical specifications of the best 3 way ball valves and explore strategies to optimize their use, ensuring operational efficiency and reliability in today's competitive market.

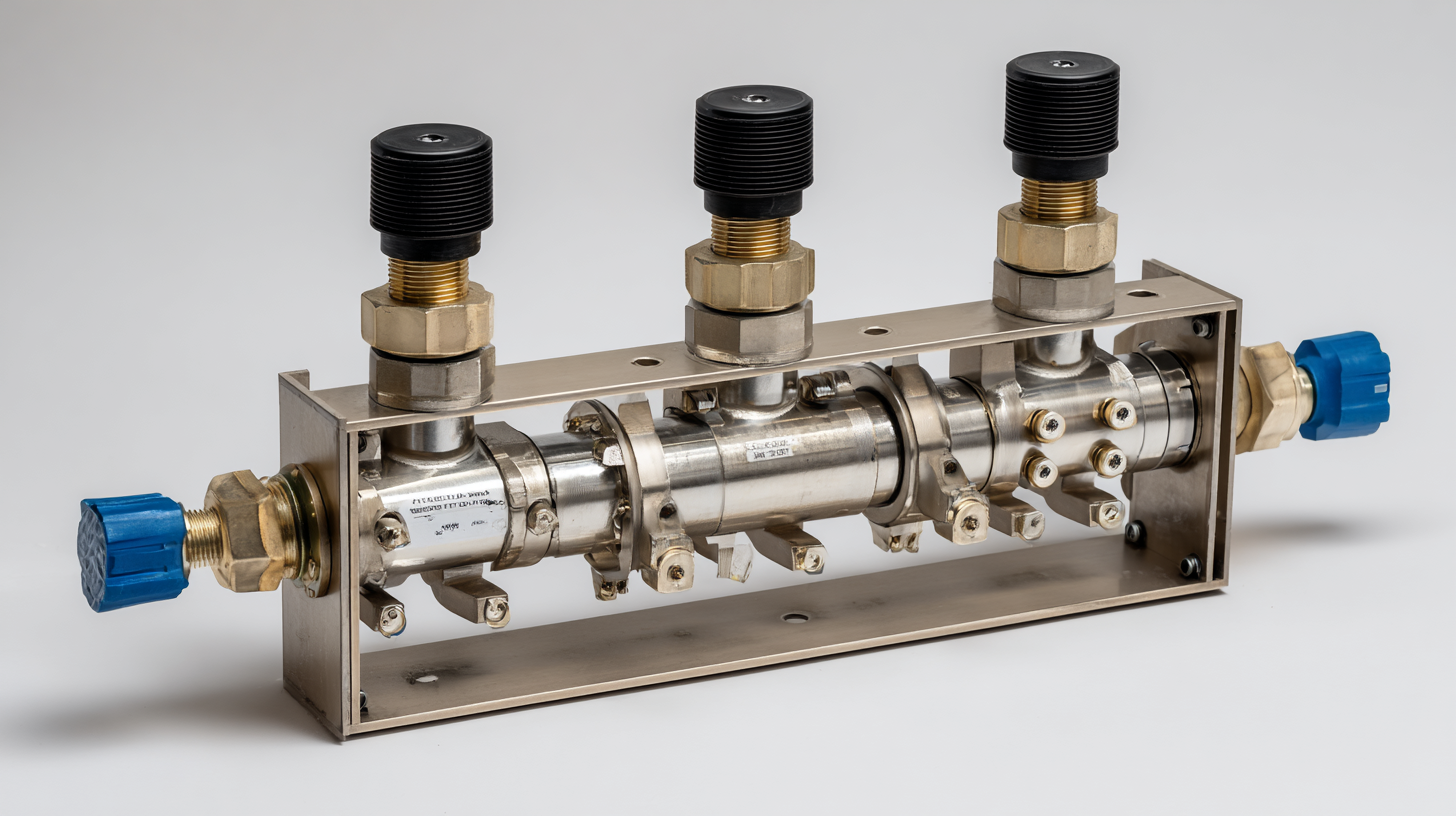

Key Features of 3 Way Ball Valves: A Comprehensive Overview

When it comes to fluid control in various industries, 3-way ball valves stand out for their versatility and efficiency. Capable of directing flow in multiple directions, these valves are essential in applications like HVAC systems, water treatment, and chemical processing. A key feature of 3-way ball valves is their configuration; they are available in L-port and T-port designs, allowing for diverse flow path options. According to industry reports, these valves can reduce pressure drops by up to 30% compared to traditional valve types, leading to significant energy savings and increased operational efficiency.

Tips: To optimize the use of 3-way ball valves, ensure proper sizing based on flow requirements to prevent cavitation issues, which can lead to premature valve failure. Additionally, regular maintenance checks can help identify wear and tear early, extending the lifespan of the valve. For installations where space is limited, consider using compact models that maintain performance without compromising quality.

Moreover, the material selection for 3-way ball valves is crucial. Valves made from corrosion-resistant materials provide longevity in harsh environments. According to recent studies, the proper selection of valve materials can enhance durability by up to 40%, making it a vital aspect of valve selection in critical applications.

Understanding the Different Types of 3 Way Ball Valves and Their Applications

Three-way ball valves are essential components in various industrial applications, offering versatile flow control solutions. These valves come in different types, including L-port and T-port designs, which cater to specific operational needs. According to a 2022 report by MarketsandMarkets, the global market for ball valves is projected to reach $18.5 billion by 2026, driven by the increasing demand in sectors such as oil and gas, water treatment, and HVAC. The L-port valve, for instance, allows for the diversion of flow between two outlets, making it ideal for applications where process media needs to be directed to multiple pipelines.

On the other hand, T-port valves are designed to connect three different pipes, providing greater flexibility in directing flow from one inlet to multiple outlets. This functionality is particularly advantageous in complex systems where re-routing of fluids is necessary. A recent analysis from Research And Markets highlights the growing need for efficient fluid control systems, indicating a compound annual growth rate (CAGR) of 5.4% in the ball valve segment through 2027. Understanding the distinct advantages of each valve type enables engineers to optimize their applications, ensuring enhanced efficiency and performance in operation.

Unlocking Efficiency: Technical Specifications of 3 Way Ball Valves

Maximizing Performance: Optimal Usage Scenarios for 3 Way Ball Valves

3-way ball valves are crucial in optimizing fluid control in a variety of industrial applications, particularly in process plants and HVAC systems. According to a recent industry report by MarketsandMarkets, the global ball valve market is projected to reach USD 15.3 billion by 2026, driven by the increasing demand for efficient flow control solutions. When considering optimal usage scenarios for 3-way ball valves, it is essential to match their configuration—L-port or T-port—to the specific requirements of the system. L-port valves are ideal for diverting flow between two outlets, while T-port valves enable mixing and redirecting flow to multiple pathways, making them suitable for diverse applications such as water treatment and chemical processing.

To maximize performance, proper sizing and material selection according to the application’s pressure and temperature ratings are crucial. For instance, selecting a valve designed for high-pressure systems can significantly reduce the risk of leaks and failures. The American Society of Mechanical Engineers (ASME) recommends rigorous testing and certifications to ensure compliance with industry standards. Additionally, regular maintenance, including inspection for wear and tear, can enhance the longevity and efficiency of these valves, ultimately leading to substantial cost savings. By aligning the valve selection with operational goals and maintenance practices, facilities can optimize their fluid handling processes significantly.

Unlocking Efficiency: Technical Specifications of the Best 3 Way Ball Valve and How to Optimize Its Use

| Specification | Details | Optimal Usage Scenarios |

|---|---|---|

| Valve Type | 3 Way Ball Valve | Diversion or Mixing Services |

| Body Material | Stainless Steel | Corrosive Fluid Applications |

| Pressure Rating | 600 PSI | High Pressure Systems |

| Temperature Range | -20°C to 200°C | Steam and Hot Water Applications |

| End Connections | Flanged, Welded, or Threaded | Flexible Installation Requirements |

| actuator Type | Electric or Pneumatic | Automated Control Systems |

| Flow Control Capability | Multi-Directional Flow | Complex Process Systems |

Comparative Analysis: Selecting the Right 3 Way Ball Valve for Your Needs

When it comes to selecting the right 3-way ball valve for your specific needs, understanding the differences in functionality and design is crucial. 3-way ball valves come in various configurations, including L-port and T-port designs, each serving distinct purposes. The L-port valve is ideal for diverting flow between two outlets, making it suitable for applications where space is limited. Conversely, the T-port valve allows for mixing or diverting flows, providing greater versatility in complex systems. Assessing your application requirements and the type of fluid to be handled will significantly impact your decision-making process.

Additionally, factors such as size, material, and pressure rating cannot be overlooked. Stainless steel valves are typically preferred for corrosive environments, while plastic valves might suffice for less demanding applications. Ensure that the valve's pressure rating aligns with your system’s specifications to prevent failures. Furthermore, consider ease of operation; options such as manual handles or automated actuators can greatly enhance efficiency. By focusing on these comparative aspects, you can confidently select a 3-way ball valve that will optimize performance and maintain operational integrity.

Maintenance Tips for Enhancing the Longevity of 3 Way Ball Valves

To enhance the longevity of 3-way ball valves, regular maintenance is essential. First and foremost, it’s crucial to keep the valve clean and free from debris. Regular inspections can help identify any buildup of sediment or foreign materials that could impede the valve's operation. Utilizing a soft cloth to wipe the exterior and ensuring the valve is not exposed to extreme environmental conditions can also prolong its life.

Lubricating the valve stem and seals periodically can prevent wear and maintain a smooth operation. Choose the right type of lubricant that is compatible with the valve materials, as using the incorrect type can lead to deterioration. Additionally, checking for leaks and ensuring that all connections are tight will help detect potential issues before they become significant problems. Implementing a scheduled maintenance routine will not only enhance the performance of your 3-way ball valves but will also save on replacement costs in the long run.