Understanding the Importance of Flow Control Valves in Modern Engineering Systems

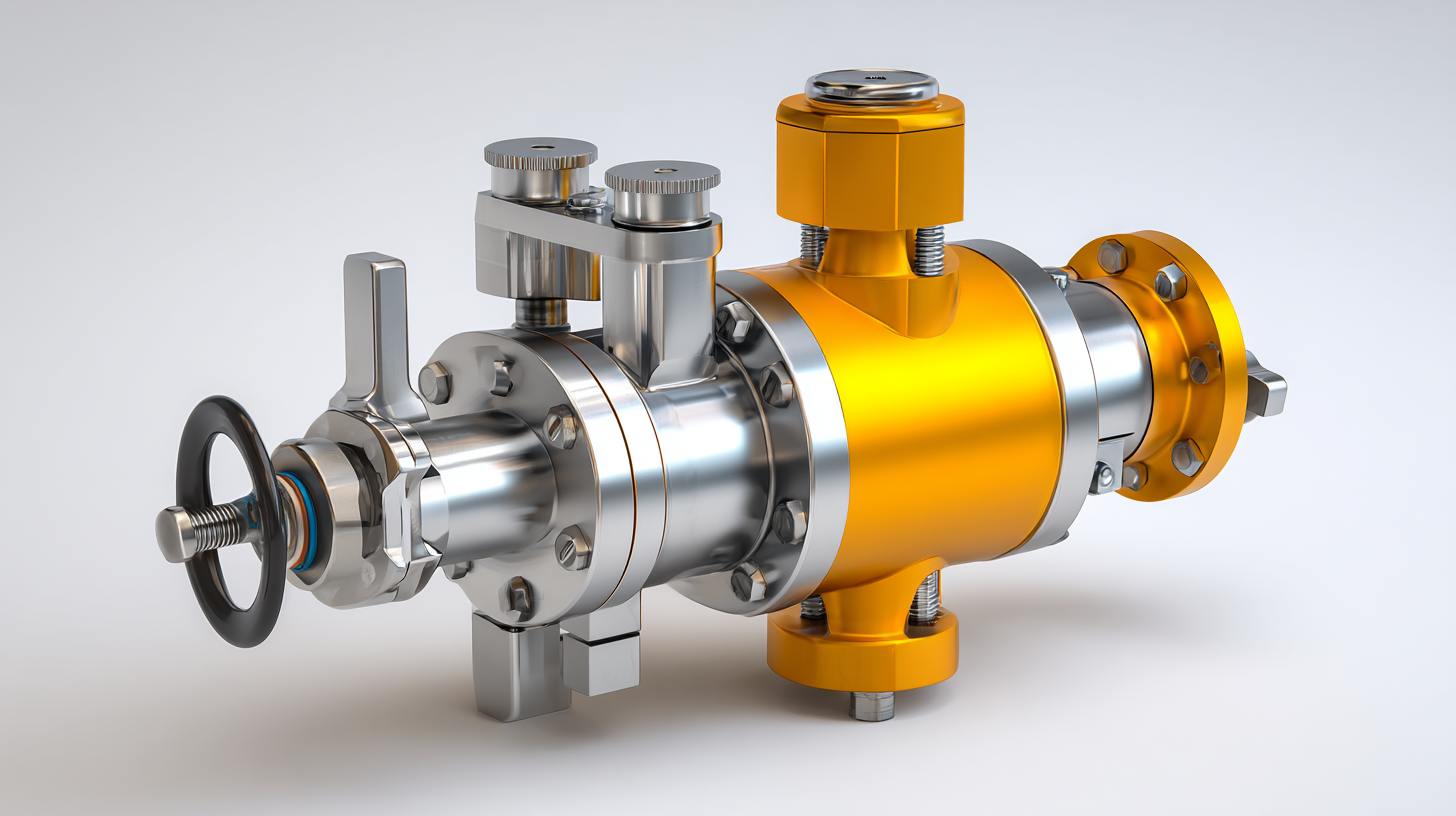

In the realm of modern engineering systems, the critical function of flow control valves cannot be overstated. As we delve into their significance, it becomes clear that these components are not merely accessory elements but vital instruments that ensure the efficient management of fluid dynamics within complex systems. Flow control valves play a pivotal role in regulating the flow rate and pressure across various applications, from industrial machinery to HVAC systems and beyond. By adjusting the flow characteristics, these valves contribute to the stability and performance of an entire system.

Understanding the importance of flow control valves requires an exploration of their design and functionality. Engineers must consider factors such as materials, pressure ratings, and operational environments when selecting the appropriate flow control valve for a specific application. The versatility of these valves, along with advances in technology, has led to innovative designs that enhance reliability and efficiency. In this discussion, we will highlight the Top 5 reasons why flow control valves are indispensable to modern engineering, illustrating their impact on system optimization and operational cost savings. Through recognizing the crucial role of flow control valves, we can appreciate how they form the backbone of streamlined processes and contribute to the overall success of engineering projects.

Definition and Functionality of Flow Control Valves in Engineering

Flow control valves are essential components in modern engineering systems, playing a critical role in managing the flow of liquids and gases. These devices regulate fluid flow by varying the size of the flow passage as directed by a control signal. According to a report by Markets and Markets, the global flow control valve market is projected to reach $12 billion by 2026, signaling the increasing relevance of these valves across various industries, including oil and gas, water treatment, and power generation.

The functionality of flow control valves is paramount in optimizing system efficiency and performance. They ensure that systems operate within desired parameters, reducing energy consumption and minimizing wear on other components. For instance, in the oil and gas sector, the effective management of flow can significantly enhance the safety and efficiency of extraction processes. A study from the American Society of Mechanical Engineers shows that improper flow regulation can lead to operational failures, resulting in potential financial losses of up to 20% of operational costs. Thus, understanding the definition and functionality of flow control valves is vital for engineers aiming to design robust and efficient engineering systems.

Types of Flow Control Valves and Their Specific Applications

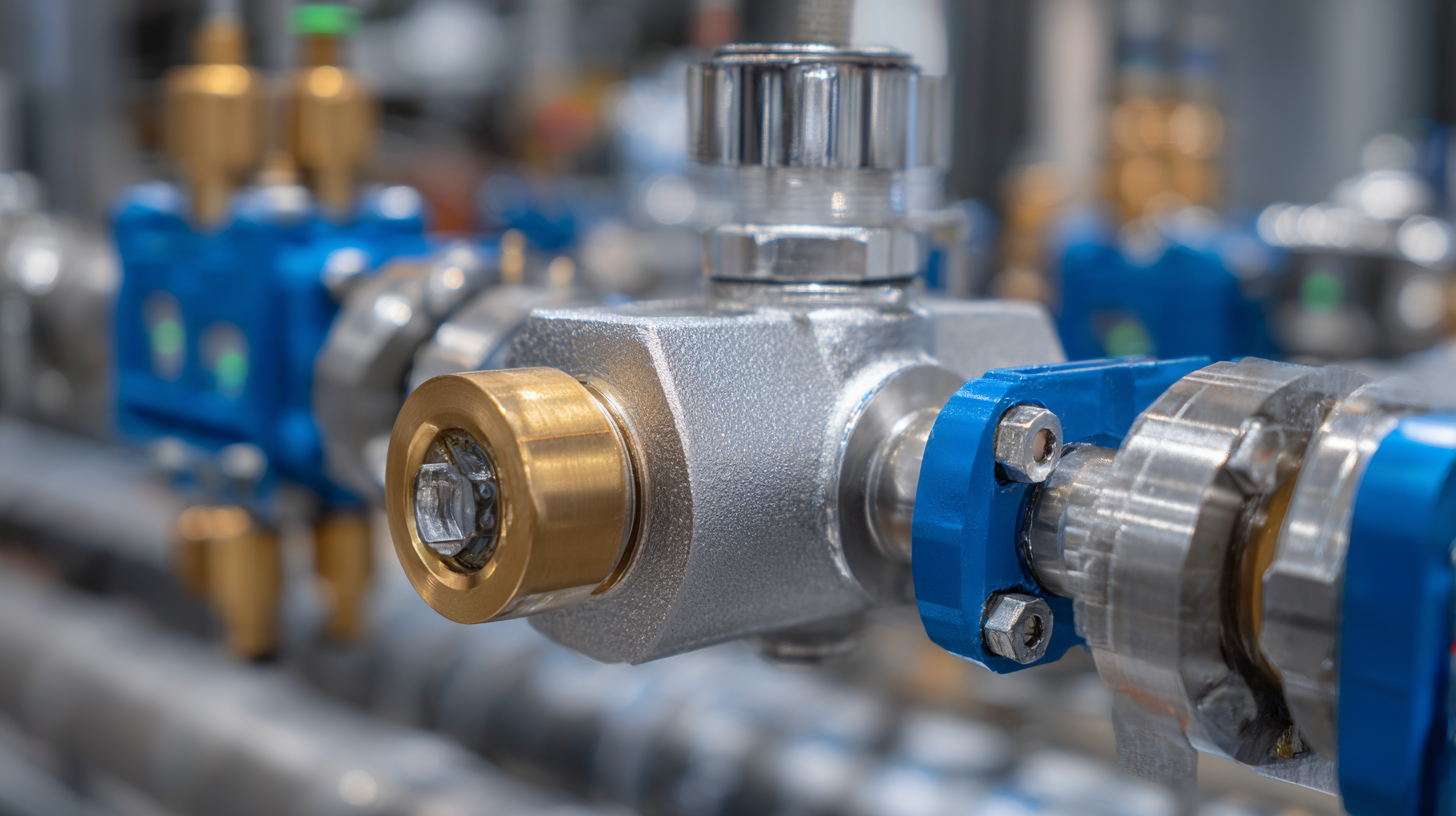

Flow control valves play a pivotal role in modern engineering systems, particularly in managing fluid dynamics across various applications. There are several types of flow control valves, each designed to serve specific functions. For instance, globe valves are widely used for their excellent throttling capability, making them ideal in cooling systems and flow regulation scenarios. According to a recent report by the Global Valve Market, the globe valve segment alone accounts for approximately 20% of the overall valve market, underscoring its significance in industrial applications.

Another essential type is the solenoid valve, which is prevalent in automated systems. These valves are electric actuated and are crucial in controlling the flow of liquids and gases with precision. Research indicates that the solenoid valve market is projected to grow by over 6% annually, driven by increasing automation in manufacturing and process industries. In addition, pressure control valves are essential in maintaining desired pressures within systems, preventing system failures and enhancing safety. The diverse functionalities of these valves highlight their importance across sectors such as oil and gas, water treatment, and HVAC systems, where fluid control is critical.

Understanding the Importance of Flow Control Valves in Modern Engineering Systems

| Type of Flow Control Valve | Description | Specific Applications | Advantages |

|---|---|---|---|

| Globe Valve | A valve with a spherical body that provides good throttling capabilities. | Water distribution, chemical processing | Precise flow control, suitable for high-pressure applications |

| Butterfly Valve | A valve that uses a rotating disc to control fluid flow. | HVAC systems, water treatment plants | Lightweight, quick operation, cost-effective |

| Ball Valve | A valve that uses a spherical disc to control flow. | Oil and gas, chemical industry | Durable, good sealing ability, quick shut-off |

| Check Valve | A valve that allows flow in one direction while preventing backflow. | Pipelines, wastewater systems | Automatic operation, protects pumps and compressors |

| Pressure Relief Valve | A valve that releases pressure when it exceeds a set limit. | Boiler systems, gas storage | Prevents system failure, enhances safety |

Importance of Flow Control Valves in Maintaining System Efficiency

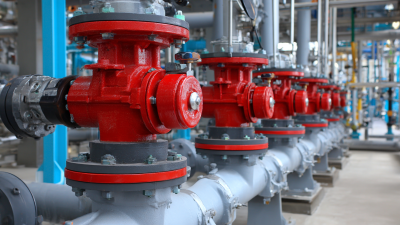

Flow control valves play a crucial role in maintaining system efficiency across various engineering applications. These devices regulate the flow of fluids, ensuring optimal performance and energy conservation. In industries such as natural gas, the need for precise control becomes paramount as fluctuating demands and environmental considerations drive the adoption of cleaner energy sources. Effective flow control not only enhances operational efficiency but also minimizes energy losses, ultimately contributing to a sustainable future.

Tips:

1. Regularly inspect your flow control valves to ensure they are functioning optimally and replace any worn components promptly.

2. Utilize computational simulations to predict how flow dynamics will change with different valve configurations, helping you make informed decisions about your system design.

The industrial valves market is witnessing significant growth, driven by a rising demand for advanced solutions in various sectors. By 2030, the control valves market alone is expected to reach $12.40 billion, highlighting the increasing importance of these devices in improving efficiency and safety. Innovations in valve technology continue to emerge, empowering industries to refine their fluid management systems and achieve better performance outcomes.

Challenges and Innovations in Flow Control Valve Technology

Flow control valves are essential components in modern engineering systems, regulating the flow of liquids and gases to ensure efficient operation. However, the technology behind these valves faces several challenges that require innovative solutions. According to a report by MarketsandMarkets, the global flow control market is expected to reach USD 33.5 billion by 2025, highlighting the critical role of flow control systems across multiple industries.

Flow control valves are essential components in modern engineering systems, regulating the flow of liquids and gases to ensure efficient operation. However, the technology behind these valves faces several challenges that require innovative solutions. According to a report by MarketsandMarkets, the global flow control market is expected to reach USD 33.5 billion by 2025, highlighting the critical role of flow control systems across multiple industries.

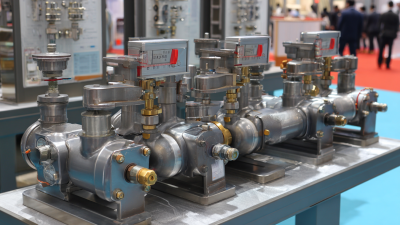

One significant challenge in flow control valve technology is the increasing demand for automation and real-time monitoring. With the rise of Industry 4.0, engineers are seeking smarter valves that can integrate with digital systems for enhanced performance analytics. Companies are innovating by developing smart valves equipped with IoT sensors that provide instantaneous feedback on flow rates and pressure, enabling predictive maintenance and improved efficiency. Additionally, as environmental regulations tighten, there is a growing need for valve designs that minimize leakage and waste. A 2022 study indicated that enhanced sealing technologies can reduce emissions by up to 30%, underscoring the importance of innovation in sustainable engineering practices.

Furthermore, advancements in materials and manufacturing techniques, such as 3D printing and composite materials, are reshaping the development of flow control valves. By implementing these innovations, manufacturers can produce lighter, more durable valves that withstand extreme conditions while maintaining accuracy and reliability. As the industry evolves, continuous research and development will be essential to overcome existing challenges and drive the future of flow control valve technology.

Future Trends in Flow Control Valve Design and Implementation

The role of flow control valves in modern engineering systems cannot be overstated, particularly in managing fluid dynamics within various applications. As the industry progresses, innovative designs and advanced materials are becoming integral to the development of flow control valves. Recent market analysis indicates that the acidic gas valve market was valued at $98.3 million in 2024 and is projected to reach $147.09 million by 2032, reflecting a compound annual growth rate of 5.1%. This growth is indicative of the increasing demand for more efficient and robust flow management solutions across diverse sectors.

As we look towards the future, the trends in flow control valve design and implementation will likely focus on automation and smart technologies. Incorporating Internet of Things (IoT) capabilities will enable real-time monitoring and control, leading to enhanced operational efficiency and reduced downtime. Additionally, the development of eco-friendly materials aims to meet the growing regulatory demands while ensuring sustainability in engineering practices.

Tips:

- When selecting a flow control valve, consider the specific requirements of your application, including pressure, temperature, and fluid characteristics.

- Stay informed about advancements in valve technology to enhance efficiency and compliance with industry standards.

- Regular maintenance and updates to your control systems can vastly improve the performance and longevity of flow valves in your engineering systems.

Related Posts

-

Understanding the Purpose and Functionality of Flow Control Valves

-

Exploring Flow Control Valve Trends and Market Growth at 2025 Canton Fair: Key Industry Insights

-

How to Choose the Best Motorized Valve for Your Industrial Needs

-

7 Effective Strategies for Choosing the Right Electric Valve

-

Unlocking Efficiency: Technical Specifications of the Best 3 Way Ball Valve and How to Optimize Its Use

-

How to Choose the Right Water Valve for Your Industrial Needs