Top Strategies for Maximizing Efficiency with Pneumatic Control Valves

In today's fast-paced industrial landscape, maximizing efficiency is imperative for businesses seeking a competitive edge. The use of pneumatic control valves plays a pivotal role in enhancing operational performance across various sectors, including manufacturing, oil and gas, and food processing.

According to a recent report from MarketsandMarkets, the global market for pneumatic control valves is projected to reach $8.5 billion by 2025, driven by the increasing demand for automation and reduction of operational costs. These valves facilitate precise control of fluid flow and pressure, ensuring optimized resource management and energy savings.

By implementing best practices and innovative strategies for integrating pneumatic control valves into existing systems, organizations can significantly boost productivity while maintaining safety and reliability. This ultimate guide outlines essential strategies for maximizing efficiency with pneumatic control valves, providing insights that can transform your operations for the better.

Understanding Pneumatic Control Valves: Key Concepts and Functionality

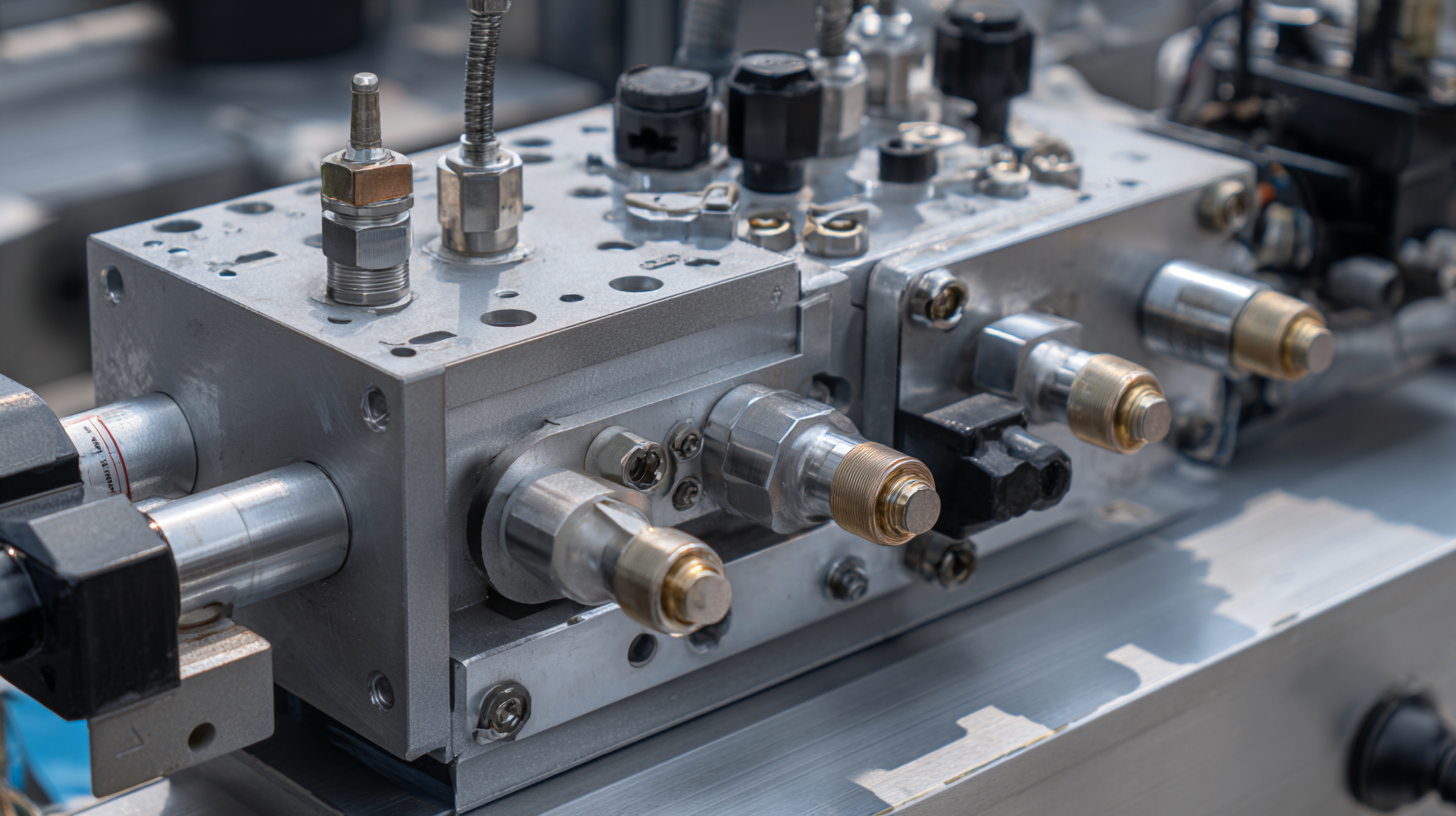

Pneumatic control valves play a vital role in industrial automation by regulating the flow and pressure of compressed air in various systems. Understanding their key concepts and functionality is essential for maximizing operational efficiency. At their core, these valves act as a gatekeeper, controlling the movement of air through a system while ensuring optimal performance and reliability. When selecting a pneumatic control valve, it’s important to consider factors such as valve type, size, and actuation method, as these elements directly influence the valve’s responsiveness and control capabilities.

Moreover, the functioning of pneumatic control valves hinges on their design and the principles of fluid dynamics. They typically consist of a body, seat, and actuator, with some models also including positioners for precise control. These valves can be categorized into various types, such as solenoid-operated, pneumatic actuated, and manual, each serving specific applications. By understanding the mechanics behind these valves, operators can implement strategies that enhance flow rates, reduce energy consumption, and decrease maintenance intervals, leading to improved system performance. Investing in the right pneumatic control valves, accompanied by proper training and maintenance, unleashes the full potential of industrial automation processes.

Top Strategies for Maximizing Efficiency with Pneumatic Control Valves

| Strategy | Description | Key Benefits | Potential Drawbacks |

|---|---|---|---|

| Regular Maintenance | Routine check-ups and servicing of pneumatic valves to prevent breakdowns. | Increased reliability and reduced downtime. | Requires dedicated time and resources. |

| Optimal Sizing | Ensure that valves are appropriately sized for the application to maintain efficiency. | Improved performance and energy savings. | Mis-sizing can lead to pressure losses or system overloads. |

| Proper Installation | Ensure installation protocols are followed to prevent leaks and inefficiencies. | Enhanced system performance and reduced leaks. | Initial installation costs and time. |

| Use of Advanced Materials | Select valves made from advanced materials to enhance durability. | Increased lifespan and lower replacement costs. | Higher upfront material costs. |

| Automation Integration | Implement automation for precise control over fluid flow. | Increased accuracy and reduced human error. | Potentially high initial investment for technology. |

Top Five Benefits of Using Pneumatic Control Valves for Industrial Applications

Pneumatic control valves are integral components in many industrial systems, delivering substantial benefits that can enhance overall operational efficiency. One of the primary advantages of using these valves is their rapid response time. According to a report by the International Society of Automation, pneumatic systems can achieve actuation speeds up to 10 times faster than their electric counterparts, making them ideal for applications requiring quick adjustments and precise control.

Pneumatic control valves are integral components in many industrial systems, delivering substantial benefits that can enhance overall operational efficiency. One of the primary advantages of using these valves is their rapid response time. According to a report by the International Society of Automation, pneumatic systems can achieve actuation speeds up to 10 times faster than their electric counterparts, making them ideal for applications requiring quick adjustments and precise control.

Another significant benefit lies in their robustness and reliability under harsh conditions. A study published by the Flow Control Journal indicates that pneumatic control valves have an operational lifespan that is, on average, 20% longer than electric valves in environments with high temperatures and humidity levels. This durability minimizes downtime and maintenance costs, presenting a compelling case for industries where continuous operation is crucial.

Additionally, pneumatic control valves are highly energy-efficient. The Compressed Air and Gas Institute notes that systems utilizing pneumatic control can operate at pressures as low as 80 psi, optimizing energy usage without sacrificing performance. This efficiency not only translates into cost savings but also supports sustainability initiatives by reducing the overall energy consumption of industrial operations.

Best Practices for Maintenance and Troubleshooting of Pneumatic Control Valves

Pneumatic control valves play a crucial role in various industrial applications, and ensuring their reliable operation is imperative for maintaining efficiency. One industry report highlights that inadequate maintenance can lead to inefficiencies, costing companies up to 20% more in operational costs due to unexpected downtimes. Therefore, implementing best practices for maintenance and troubleshooting is essential. Regular inspections, cleaning of valve components, and ensuring proper lubrication can significantly prolong the lifespan of these valves.

Technicians should be aware of common issues that can affect pneumatic control valves, such as air leaks or improper valve actuation. For instance, air leaks can account for up to 30% of compressed air usage in a system, emphasizing the need for timely troubleshooting. Incorporating a systematic approach to inspection, guided by comprehensive training resources, can empower technicians to effectively address these problems. As shown in recent findings, organizations that invest in continuous education for their workforce, especially regarding air system valve troubleshooting, see a marked increase in overall equipment efficiency and reduced maintenance costs.

Innovative Automation Solutions to Enhance Pneumatic Control Valves Efficiency

Innovative automation solutions are revolutionizing the efficiency of pneumatic control valves, driving significant improvements in various industrial applications. According to a recent industry report, companies that implement automated control systems can enhance valve performance by up to 30%, resulting in reduced operational costs and improved system reliability. By incorporating advanced sensors and actuator technologies, organizations can achieve real-time monitoring and adjustment, optimizing the operation of pneumatic systems.

One effective strategy to maximize efficiency is the integration of predictive maintenance practices. Utilizing analytics and IoT technology allows businesses to anticipate failures before they occur, reducing downtime and maintenance costs. For instance, data from market studies indicates that predictive maintenance can decrease unplanned outages by as much as 50%, thus significantly improving operational continuity.

Another key tip is to prioritize valve selection based on the specific requirements of the system. Choosing the right materials and designs tailored to application conditions can enhance durability and performance. Research reveals that using high-performance seals and valve bodies can lead to a 25% increase in operational efficiency, allowing facilities to maintain high standards of productivity while minimizing energy consumption. These strategies highlight the importance of innovative automation in optimizing pneumatic control valves and driving industry advancements.

Efficiency Enhancement in Pneumatic Control Valves

This chart illustrates the percentage efficiency gains from various innovative automation solutions applied to pneumatic control valves. It highlights the impact of different strategies on enhancing overall performance.

Maximizing System Performance: Integration Tips for Pneumatic Control Valves

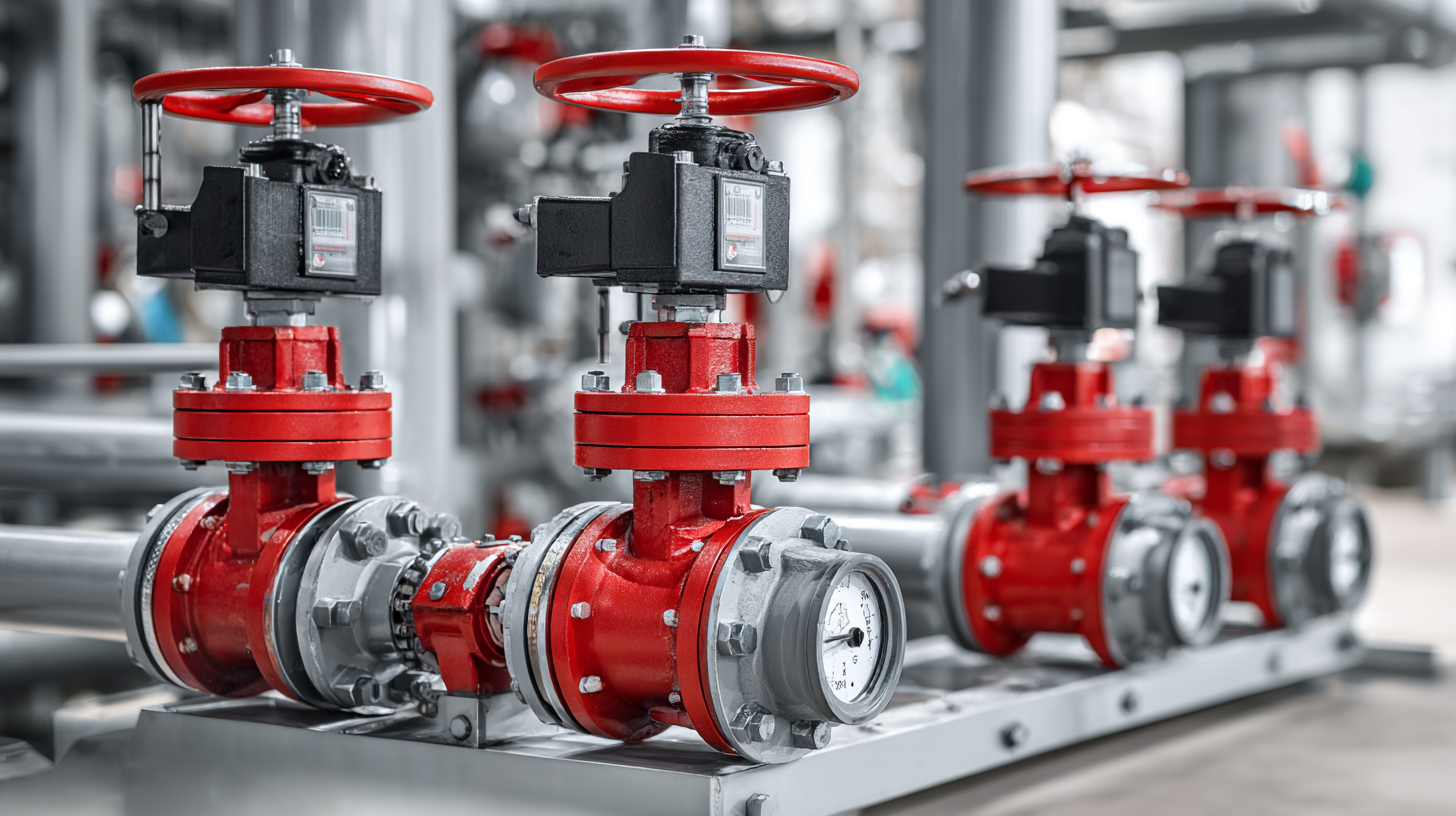

When it comes to enhancing system performance in PNEUMATIC SYSTEMS, the integration of

pneumatic control valves plays a pivotal role. By selecting the right control valves,

you can manage flow rates, pressure, and direction with high precision, enabling your system to operate efficiently.

Understanding the specific requirements of your application is crucial; factors such as

valve response time, compatibility with fluids, and durability should factor into your selection process.

Utilizing valves with smart technology can further streamline operations,

allowing for real-time monitoring and adjustments that lead to optimal system performance.

When it comes to enhancing system performance in PNEUMATIC SYSTEMS, the integration of

pneumatic control valves plays a pivotal role. By selecting the right control valves,

you can manage flow rates, pressure, and direction with high precision, enabling your system to operate efficiently.

Understanding the specific requirements of your application is crucial; factors such as

valve response time, compatibility with fluids, and durability should factor into your selection process.

Utilizing valves with smart technology can further streamline operations,

allowing for real-time monitoring and adjustments that lead to optimal system performance.

To maximize the effectiveness of pneumatic control valves, proper installation and configuration are essential. Ensure that valves are placed strategically within the system to facilitate optimal airflow and reduce pressure losses. Additionally, incorporating advanced control systems that can integrate seamlessly with your pneumatic valves can enable automation, minimizing manual intervention and potential errors. Regular maintenance, including software updates for smart valves, will ensure that the system continues to function at peak efficiency, prolonging the lifespan of the components and reducing overall operational costs. By paying careful attention to integration and ongoing management, you can greatly enhance the performance and reliability of pneumatic control systems.