What Makes a Pneumatic Ball Valve the Best Choice for Industrial Applications

In the world of industrial applications, choosing the right valve can significantly impact efficiency, safety, and overall operational effectiveness. Among the various options available, the pneumatic ball valve stands out as a premier choice for many industries. Known for its exceptional reliability and performance, the pneumatic ball valve operates with compressed air, allowing for quick and precise control of fluid flow. Its unique design minimizes pressure drop and provides a tight seal, making it ideal for high-pressure and high-flow systems. This blog will delve into the key advantages of pneumatic ball valves, exploring why they are often considered the best option for industrial applications. By examining their functionality, benefits, and suitability across different sectors, we aim to highlight how incorporating pneumatic ball valves can enhance operational efficiency and ensure long-term reliability in various industrial environments.

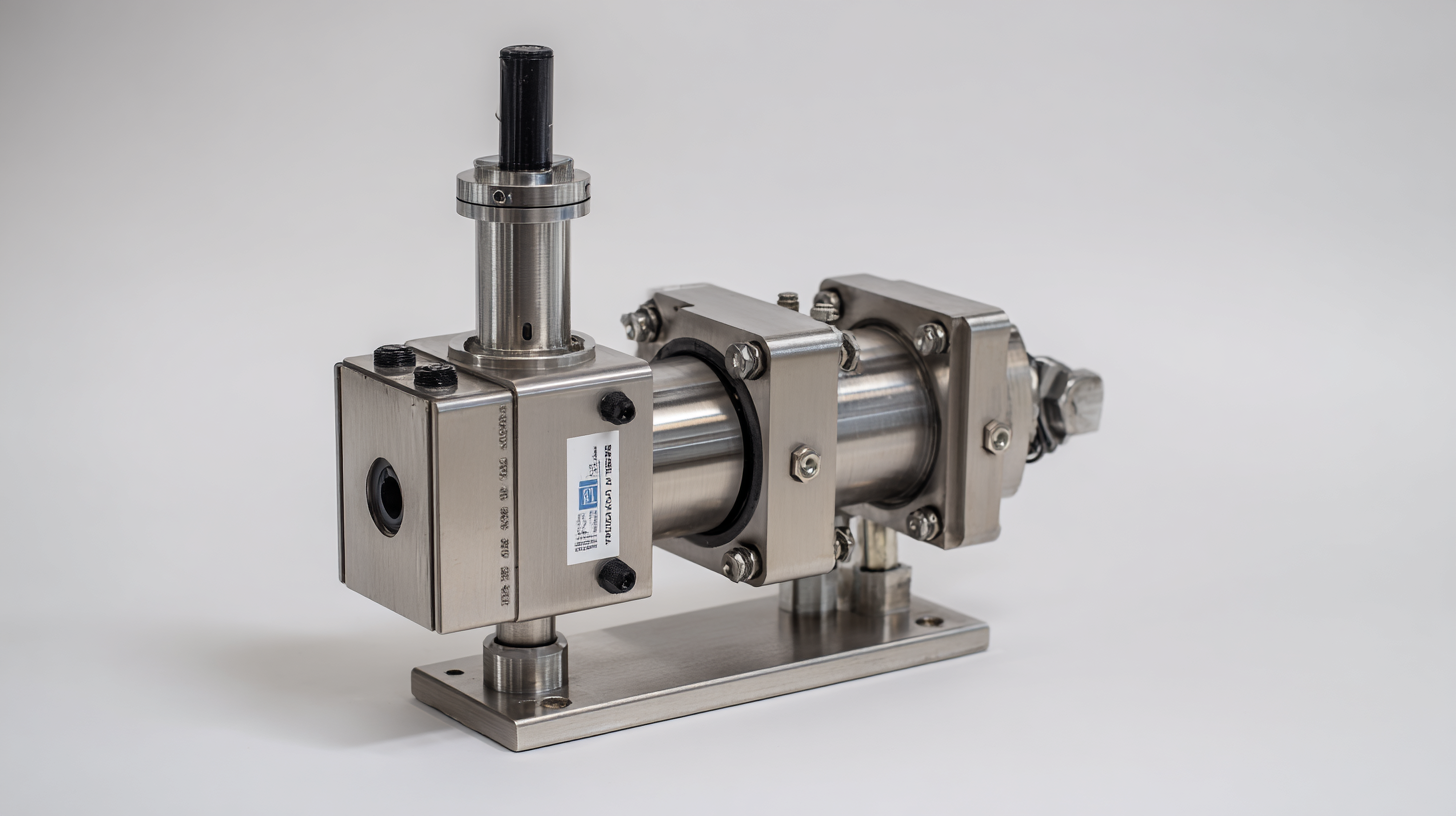

Key Features of Pneumatic Ball Valves in Industrial Settings

Pneumatic ball valves are increasingly recognized as an optimal choice for industrial applications due to their unique features tailored for demanding environments. One of the most significant characteristics is their rapid actuation capability. Powered by compressed air, these valves can open and close quickly, allowing for efficient fluid control in manufacturing and processing systems. This quick response time is crucial for applications requiring precise flow regulation, enhancing operational efficiency and minimizing downtime.

Another key feature is the durability of pneumatic ball valves. Built with robust materials like stainless steel, they can withstand extreme temperatures and pressures, making them suitable for various industrial settings. Additionally, their design reduces wear and tear, ensuring a longer lifespan compared to other types of valves. The tight sealing provided by the ball mechanism also prevents leaks, which is essential for maintaining safety and reliability in industrial operations. These attributes make pneumatic ball valves a preferred solution for industries such as chemical processing, water treatment, and oil and gas, where performance and reliability are paramount.

Comparative Analysis: Pneumatic Ball Valves vs. Other Valve Types

When it comes to industrial applications, choosing the right valve is crucial for ensuring efficiency and reliability. Pneumatic ball valves stand out against other valve types, such as globe valves and gate valves, primarily due to their quick actuation and tight sealing capabilities. Unlike globe valves, which require multiple turns to open and close, pneumatic ball valves can switch from fully open to fully closed in just a quarter turn. This rapid response time minimizes downtime and enhances system performance, making them ideal for processes that demand swift operational adjustments.

Moreover, the inherent design of pneumatic ball valves offers superior flow characteristics compared to other types. The ball mechanism allows for unrestricted flow, significantly reducing pressure drops and improving energy efficiency. In contrast, gate valves, while effective for on/off control, can introduce substantial turbulence and resistance. Additionally, the durable materials often used in pneumatic ball valves provide excellent resistance to corrosion and wear, ensuring longevity in demanding environments. By understanding these comparative advantages, industries can make informed decisions that enhance their operational efficiency and reduce maintenance costs.

Cost-Effectiveness of Pneumatic Ball Valves for Industrial Applications

In industrial applications, cost-effectiveness is a key consideration when selecting valves, and pneumatic ball valves stand out as an optimal choice. Their simple design allows for reduced manufacturing costs and easier maintenance compared to more complex valve systems. By efficiently controlling the flow of fluids, pneumatic ball valves help minimize operational costs, making them a smart investment for manufacturers aiming to enhance their bottom line.

**Tip:** When comparing pneumatic ball valves, consider the total cost of ownership, which includes initial purchase price, maintenance costs, and energy efficiency. This holistic approach will help you identify the most cost-effective option for your specific application.

Furthermore, the durability and longevity of pneumatic ball valves contribute to their cost-effectiveness. They are designed to withstand high pressures and temperatures, reducing the frequency of replacements. Over time, this reliability translates to significant savings in both parts and labor.

**Tip:** Always evaluate the material selection of pneumatic ball valves to ensure compatibility with the substances they will handle. Choosing the right materials can prevent corrosion and degradation, further extending the life of the valves and lowering overall costs.

Installation and Maintenance Benefits of Pneumatic Ball Valves

Pneumatic ball valves offer significant advantages in installation and maintenance, making them a preferred choice in various industrial applications. One of the key benefits during installation is their compact design, which allows for easy integration into existing piping systems without requiring extensive modifications. Additionally, the simple actuator mechanism of pneumatic ball valves streamlines setup processes, reducing labor costs and time associated with valve installation.

When it comes to maintenance, pneumatic ball valves stand out for their reliability and ease of operation. Their straightforward structure means that routine checks and servicing require less technical expertise and can often be performed quickly. Many models are designed with fewer moving parts, which diminishes the probability of failure and minimizes downtime. Furthermore, the ability to quickly isolate the valve for maintenance purposes eliminates the need to shut down entire systems, thereby enhancing operational efficiency in industrial environments.

Benefits of Pneumatic Ball Valves for Industrial Applications

Real-World Applications: Where Pneumatic Ball Valves Excel

Pneumatic ball valves have become integral to various industrial applications due to their ability to provide reliable control of fluid flow in high-pressure environments. In sectors such as oil and gas, chemicals, and water treatment, these valves are engineered to withstand extreme conditions while ensuring minimal leakage. According to a report by Grand View Research, the global industrial valve market is expected to reach USD 90.79 billion by 2025, with pneumatic actuation increasingly favored for its efficiency and speed, particularly in automated systems.

In real-world scenarios, pneumatic ball valves excel in processes requiring rapid on/off control. For instance, in the petrochemical industry, studies have shown that the use of pneumatic actuators in ball valves can reduce response times by up to 50% compared to traditional valve systems. This swift actuation minimizes downtime during process changes, ultimately boosting productivity. Furthermore, their compact design and straightforward installation make pneumatic ball valves an optimal choice for facilities looking to optimize space and streamline operations, ensuring they remain a top selection in industrial environments.

What Makes a Pneumatic Ball Valve the Best Choice for Industrial Applications - Real-World Applications: Where Pneumatic Ball Valves Excel

| Application | Industry | Advantages | Operational Environment |

|---|---|---|---|

| Water Treatment | Environmental | Precision control, quick response | Wet, corrosive conditions |

| Food Processing | Food & Beverage | Hygienic design, easy to clean | Clean, controlled environment |

| Chemical Processing | Chemical Manufacturing | Resistance to corrosive fluids | Harsh, potentially hazardous |

| Oil & Gas | Energy | High pressure handling, reliability | High pressure, variable temperatures |

| Pharmaceutical Production | Pharmaceuticals | Precision and safety | Sterile, controlled conditions |