The Ultimate Guide to Choosing the Right Stainless Steel Ball Valve for Your Industrial Needs

In today's industrial landscape, the demand for reliable and durable components is paramount, particularly regarding fluid control systems. Among these components, the stainless steel ball valve stands out for its excellent corrosion resistance, strength, and longevity. According to a recent market analysis by TechSci Research, the global ball valve market is expected to reach USD 10.50 billion by 2026, fueled by increasing investments in infrastructure and a growing emphasis on energy efficiency.

Stainless steel ball valves, known for their ability to handle high pressure and temperature fluctuations, play a critical role in various industries, including oil and gas, water treatment, and chemical processing. As industries evolve, understanding how to choose the right stainless steel ball valve tailored to specific operational needs is essential for optimizing performance and ensuring safety.

This guide aims to equip readers with essential tips and insights into selecting the most suitable stainless steel ball valve for their industrial applications.

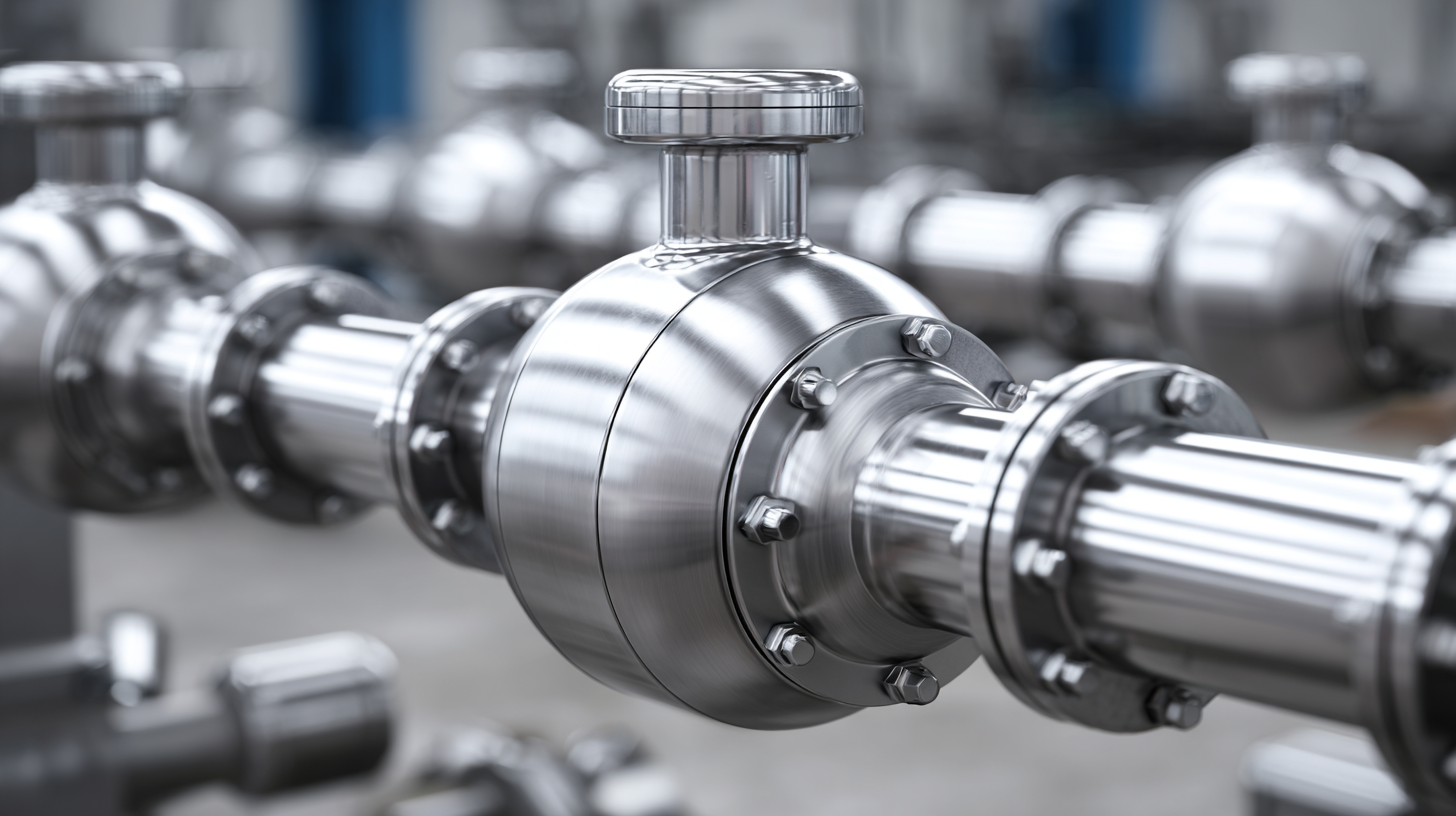

Understanding Stainless Steel Ball Valve Types and Their Applications in Industry

When it comes to selecting the appropriate stainless steel ball valve for industrial applications, it's essential to understand the various types available and their specific uses.

Stainless steel ball valves are favored in many sectors due to their durability, resistance to corrosion, and ability to handle high temperatures and pressures.

The most common types include full-port, reduced-port, and V-port ball valves.

Full-port valves, which have a larger ball that allows for maximum flow, are ideal for applications where minimal pressure loss is critical.

In contrast, reduced-port valves are designed for applications where space is limited and flow requirements are lower.

These valves help save on materials and costs while still delivering adequate performance.

V-port valves, featuring a V-shaped ball, are specifically designed for throttling and flow control, making them suitable for processes where precise flow regulation is necessary.

Understanding these variations will aid industrial professionals in selecting the right valve type tailored to their operational needs, ensuring efficiency and reliability in their systems.

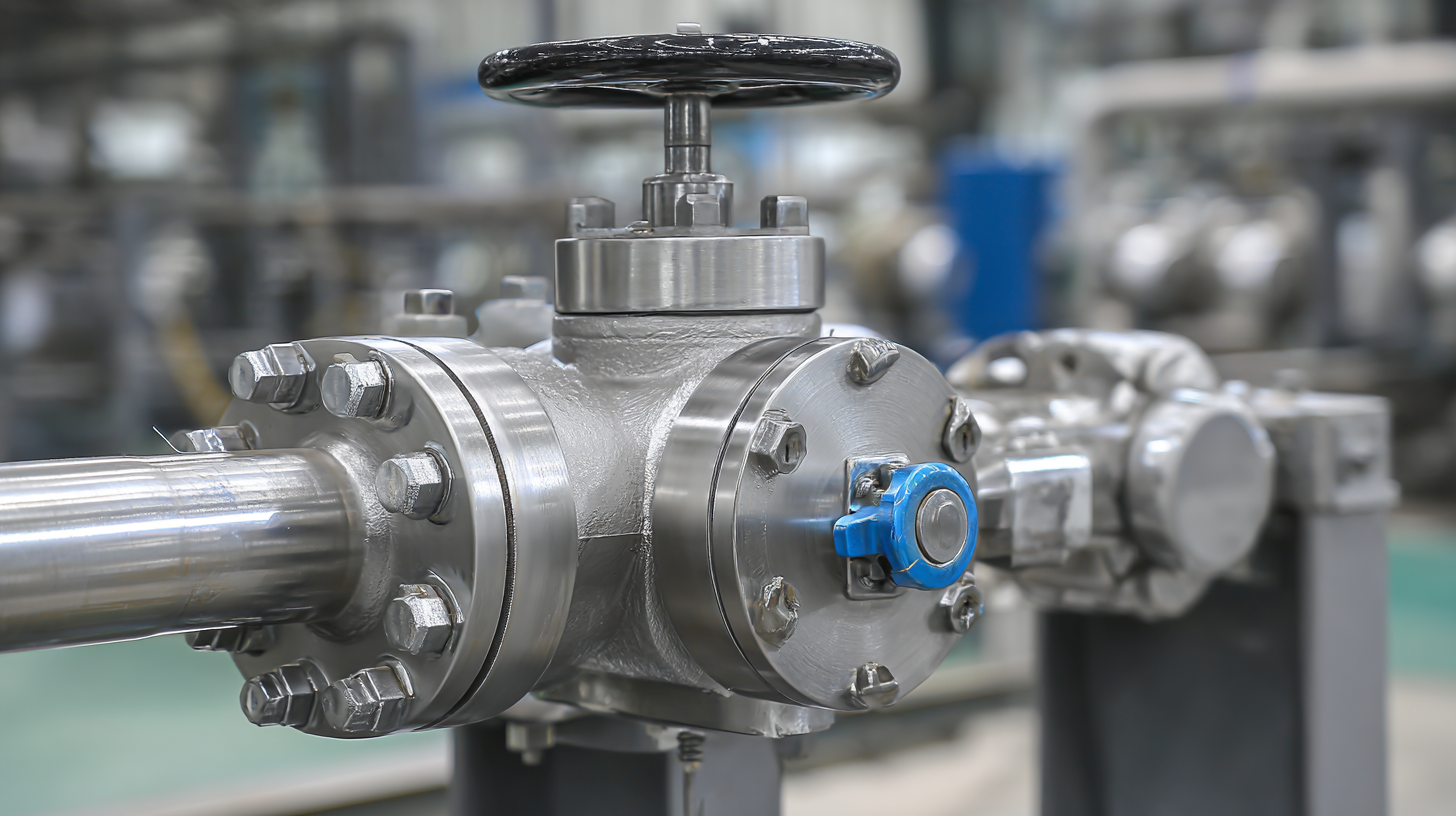

Key Factors to Consider when Selecting Stainless Steel Ball Valves for Specific Media

When selecting stainless steel ball valves for specific media in industrial applications, several key factors must be considered to ensure optimal performance and longevity. First, understanding the chemical compatibility of the valve's materials with the media is crucial. According to a report by the Valve Manufacturers Association, improper material selection can lead to premature failure, costing industries thousands in maintenance and replacements. It’s essential to check compatibility charts or consult with manufacturers to confirm that the stainless steel used can withstand the corrosive nature of the media involved.

Additionally, pressure and temperature ratings are vital. Different applications may operate under varying pressures and temperatures that can affect valve integrity. As noted in a 2022 industry analysis, stainless steel ball valves can typically handle pressures up to 6000 psi, but it's important to verify the specifications to prevent leaks or bursts.

Tips: Always inspect the valve design, ensuring it fits the required service conditions, and consider features like blowout-proof stems or double-block-and-bleed functionality for safety. Lastly, regular maintenance and monitoring can significantly extend the valve's lifespan, reducing unexpected downtimes.

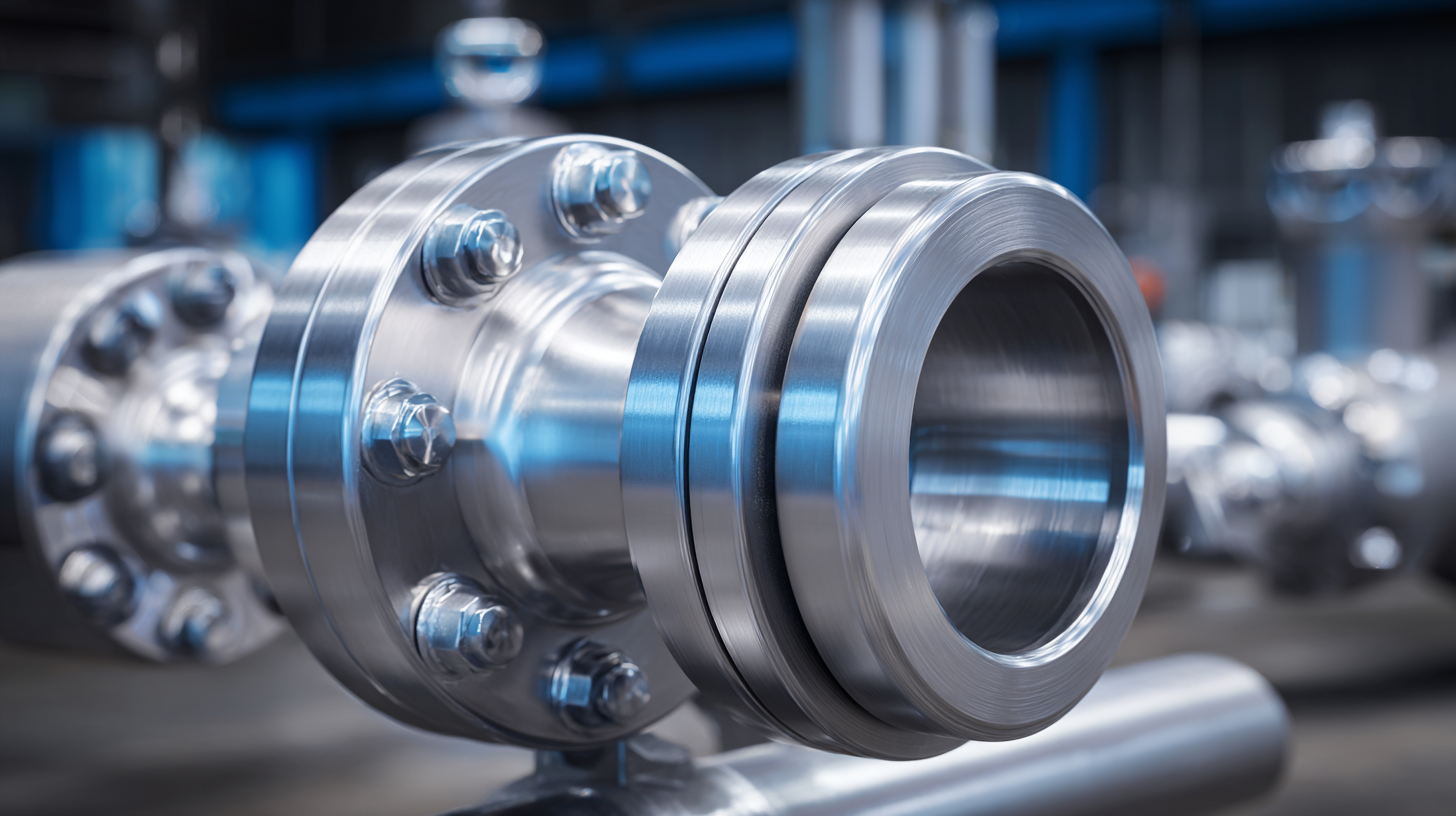

Analyzing Pressure Ratings and Temperature Ranges of Stainless Steel Ball Valves

When selecting stainless steel ball valves for industrial applications, understanding pressure ratings and temperature ranges is crucial. Pressure ratings indicate the maximum pressure the valve can withstand without failure, and this is often categorized into ANSI classes like 150, 300, or even 600. It’s essential to choose a valve that suits the pressure requirements of your system to ensure safe and reliable operation. A valve that is rated too low for the application could lead to leaks or catastrophic failure.

Temperature ranges are equally important, as they determine the valve's performance under different thermal conditions. Stainless steel ball valves typically have a temperature range that can accommodate various industrial processes, but factors such as the valve's design, seat material, and application conditions play a significant role. It’s vital to consider both the ambient and process temperatures to prevent thermal expansion issues or degradation of materials, which could compromise functionality and safety. Thus, a thorough analysis of both pressure ratings and temperature ranges will help in selecting the optimal stainless steel ball valve for your specific industrial needs.

Comparative Analysis of Stainless Steel Grades for Enhanced Corrosion Resistance in Valves

When selecting stainless steel ball valves for industrial applications, understanding the differences among stainless steel grades is crucial for ensuring enhanced corrosion resistance. According to the American Society for Testing and Materials (ASTM), the common grades used in valve construction are 304 and 316 stainless steel. Grade 304 is known for its good corrosion resistance and high strength, but when exposed to harsh environments, especially those involving chlorides, Grade 316 is often preferred due to its superior resistance attributed to the addition of molybdenum. Studies show that the corrosion rate of Grade 316 can be up to 10 times lower than that of Grade 304 in saline environments, which can significantly prolong the service life of valves in marine or chemical processing applications.

Moreover, the corrosion resistance of stainless steel valves can also be evaluated through the pitting resistance equivalent number (PREN), an important metric in the industry. The PREN for Grade 316 typically ranges from 21 to 24, while Grade 304 averages around 19. This increase in PREN indicates that Grade 316 valves are significantly more resistant to localized corrosion, making them a better choice for industries requiring long-term reliability in corrosive conditions. Utilizing valves made from the appropriate grade can lead to reduced maintenance costs and downtime, ultimately contributing to improved efficiency and safety in industrial operations.

The Ultimate Guide to Choosing the Right Stainless Steel Ball Valve for Your Industrial Needs

| Stainless Steel Grade | Corrosion Resistance (Rating) | Temperature Resistance (°C) | Applications | Common Uses |

|---|---|---|---|---|

| 304 | Good | -196 to 870 | Food Processing, Chemical Handling | Pipes, Tubes, Ball Valves |

| 316 | Excellent | -196 to 870 | Marine, Pharmaceutical, Food Industry | Heat Exchangers, Valves, Pumps |

| 321 | Good | -200 to 900 | Aerospace, Gas Turbines | Exhaust Systems, Valve bodies |

| 347 | Very Good | -200 to 870 | High Temperature Applications | Power Generation, Boiler Systems |

| 2205 | Excellent | -50 to 300 | Oil & Gas, Marine | Pipeline, Ball Valves, Pressure Vessels |

Industry Standards and Certifications: Ensuring Compliance in Stainless Steel Ball Valve Selection

When selecting a stainless steel ball valve for industrial applications, understanding industry standards and certifications is crucial. Compliance with standards such as the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) is essential for ensuring the reliability and safety of the valve in various operating conditions. These organizations establish benchmarks for design, manufacturing processes, and material quality, which aid in the selection of valves that can withstand demanding environments.

Moreover, certifications like ISO 9001 and API 6D further reinforce the credibility of the ball valve. ISO 9001 ensures that manufacturers adhere to quality management systems, while API 6D focuses on the quality of valves used in pipeline applications. These certifications not only verify that the valves meet specific performance criteria but also enhance the overall confidence in the product’s longevity and effectiveness. By prioritizing compliance with these standards, industries can avoid costly mistakes and ensure efficient operations.

The Ultimate Guide to Choosing the Right Stainless Steel Ball Valve

This chart illustrates the most common industrial applications of stainless steel ball valves and their corresponding usage percentage based on a recent industry survey.

Related Posts

-

What Defines an Actuated Ball Valve and Its Importance in Industrial Applications

-

Mastering the Basics of 3 Way Ball Valve Installation and Maintenance Guide

-

7 Essential Benefits of Using High Pressure Ball Valves in Industrial Applications

-

7 Effective Strategies for Choosing the Right Electric Valve

-

Understanding the Benefits and Applications of PVC Ball Valves in Modern Plumbing Systems

-

How to Choose the Right Water Valve for Your Plumbing Needs